Physical Image

Welcome to the official website of Hubei TrueLight 3D Sensing Technology Ltd.!

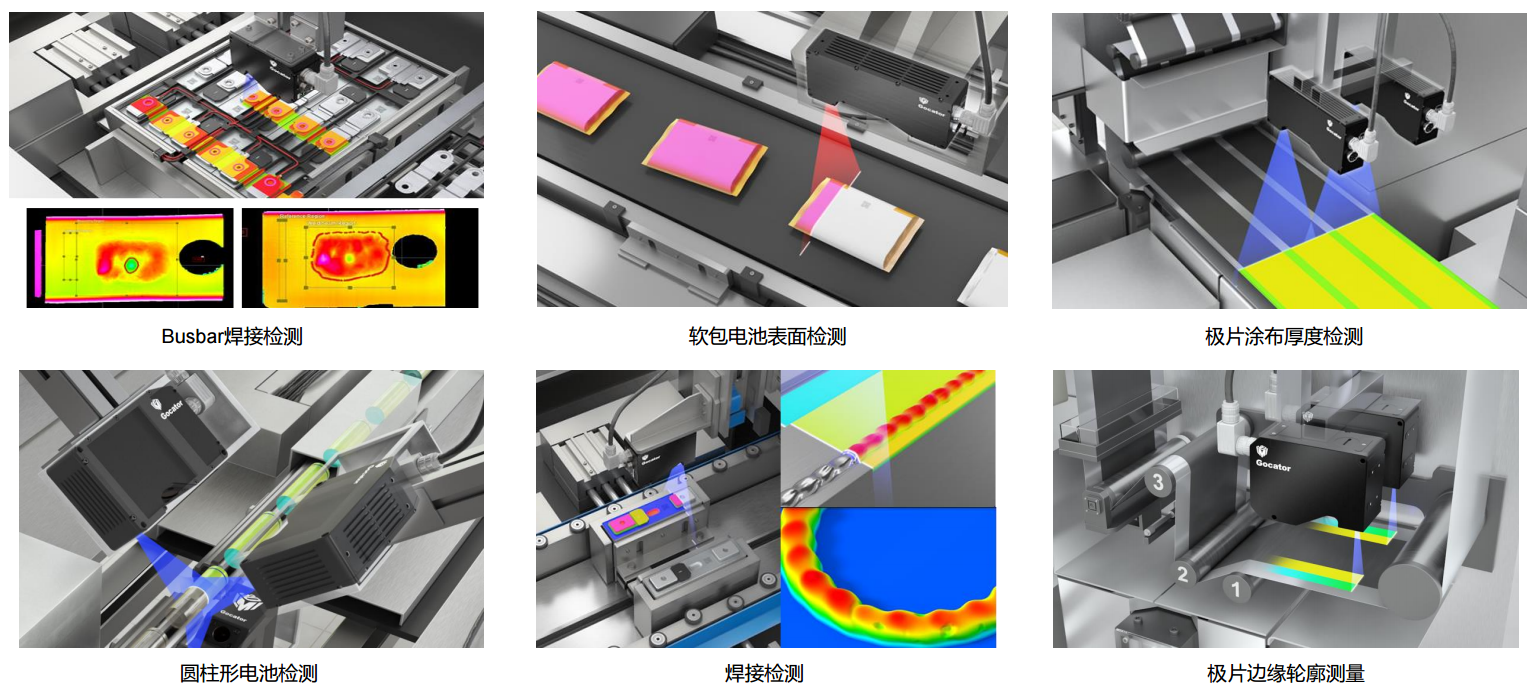

New energy battery

| √ Improve Detection Accuracy | √ Increase Production Efficiency | √ Industry-Customized Deployment | √ Reduce Costs and Increase Efficiency |

| Yield ≥99.5%, ensuring stable production line and steadily improving detection accuracy. | Machine-enabled production, meeting the needs of 24-hour fully automated production lines, and improving overall efficiency. | Based on different production line environments and production methods, customized solutions are configured to create an automated intelligent factory. | Optimize work processes, improve efficiency, shorten the investment return cycle, and flexibly meet production needs. |

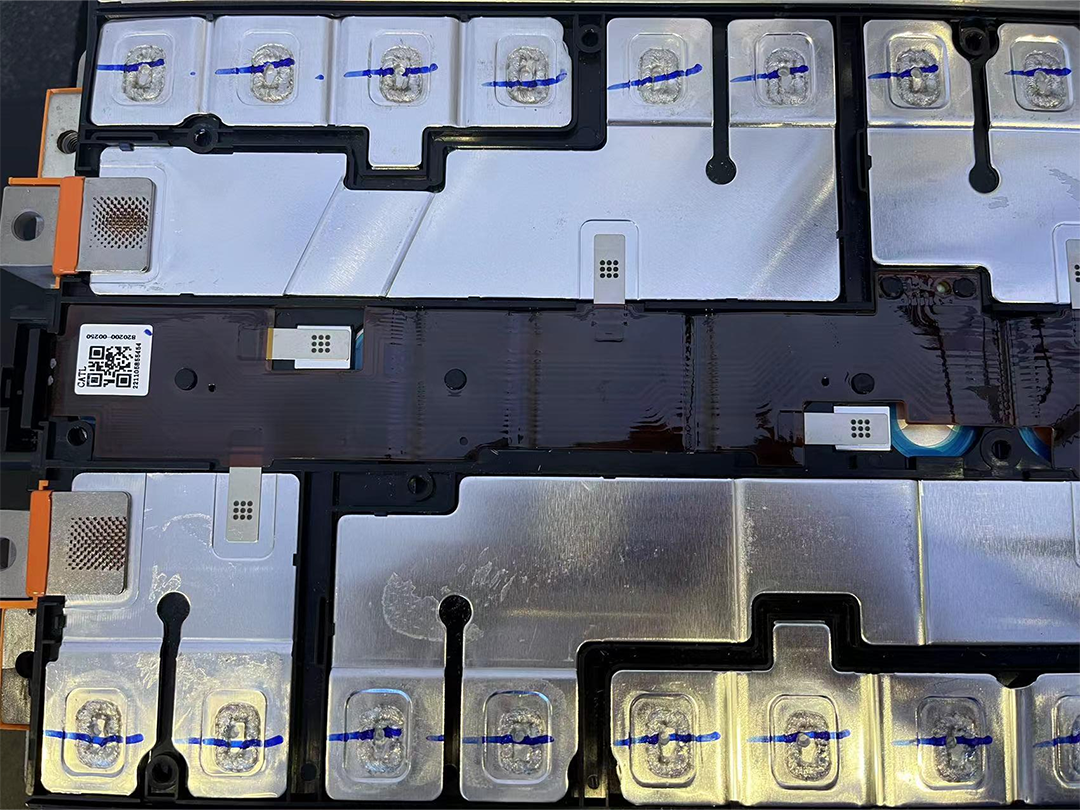

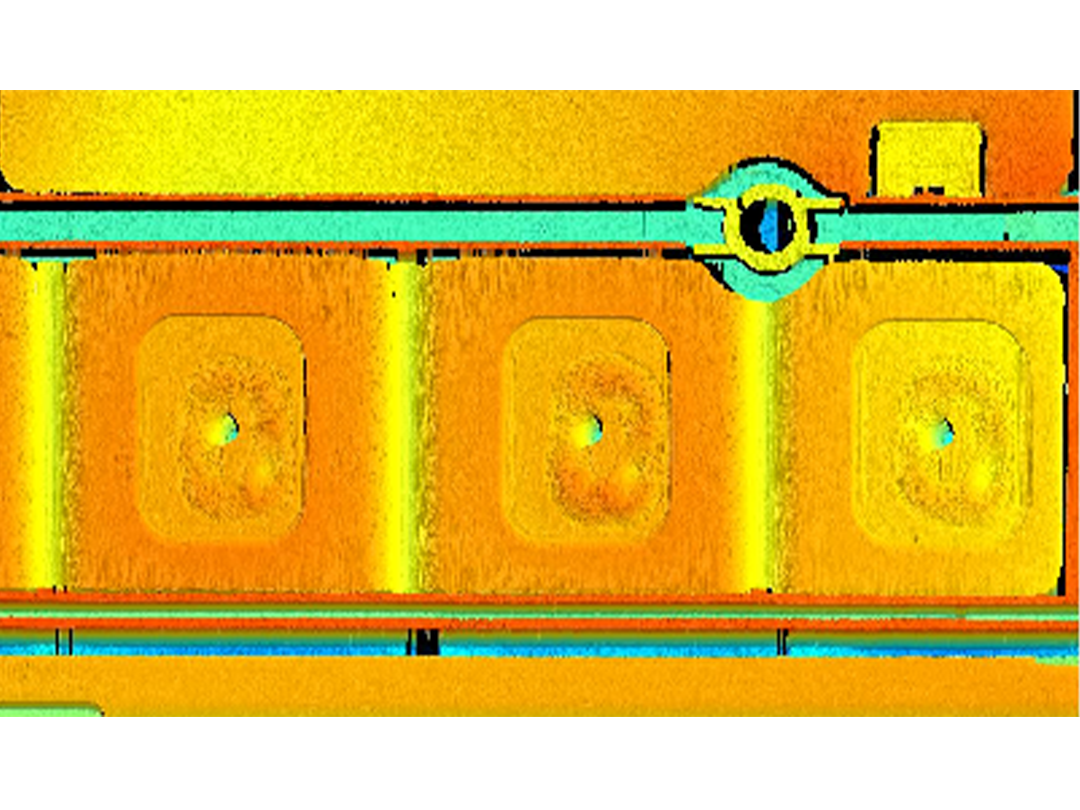

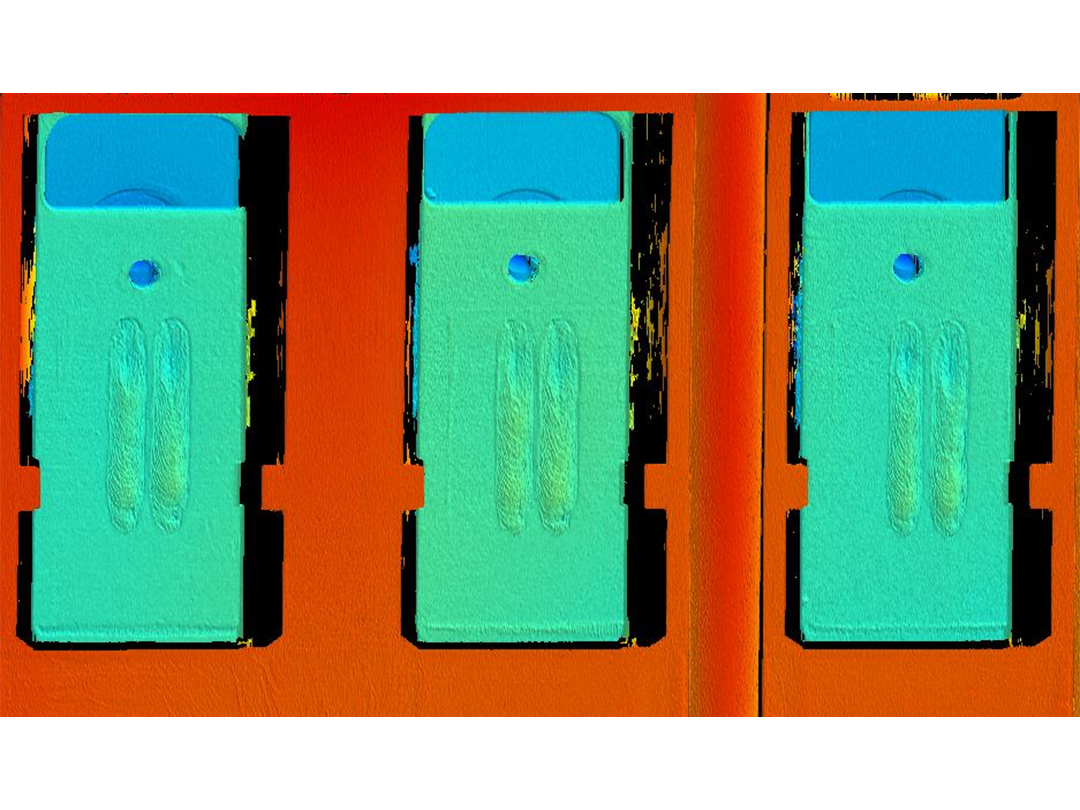

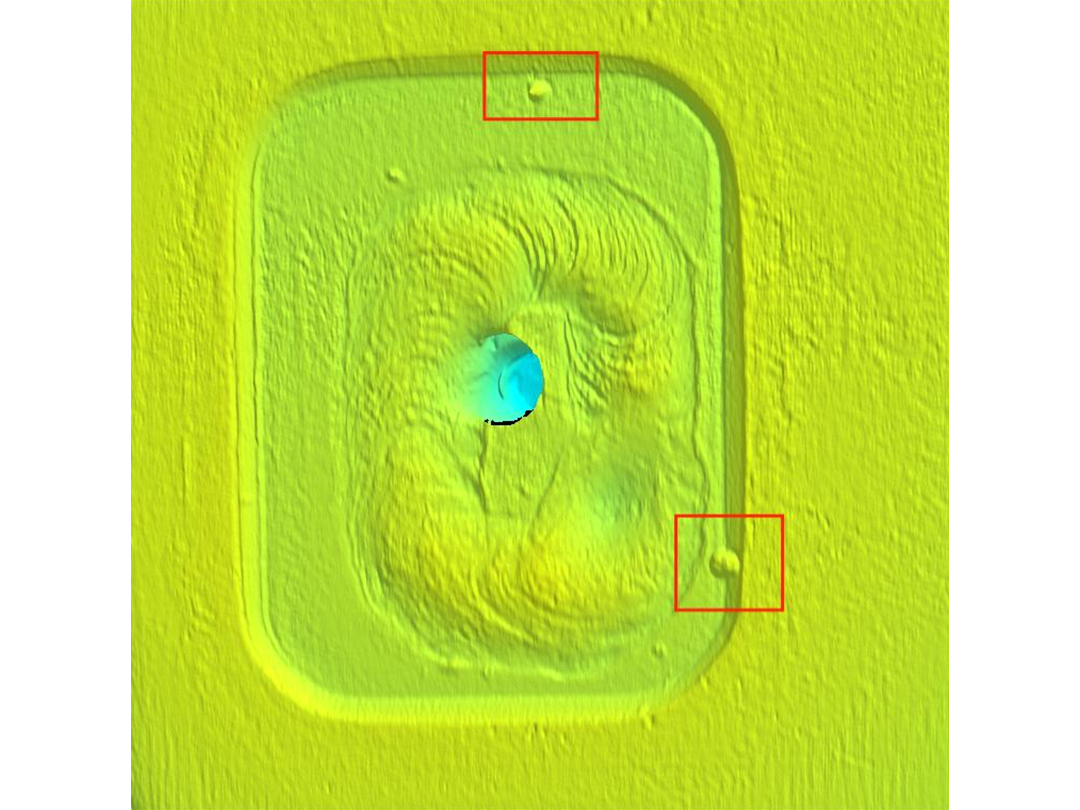

Detection Needs:Defect detection of busbars in new energy battery module

Application Scenarios:Leading enterprises in the new energy battery industry

Defect detection of battery module busbars is achieved by mounting a 3D sensor.

Functions Achieved |

1. Automatic positioning, picking, and handling of materials 2. Automatic defect inspection of battery module busbars |

Algorithm Fusion |

Point cloud stitching, target detection, 3D perception |

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Contact Us

Address:

Wuhan Headquarters:Floor 1 & 4, Entrance D, Building 2, Innovation Base, Huazhong University Of Science And Technology, Wuhan

Suzhou Office Address:Room 606, Building 5, Sip Ic Industrial Park, No.11 Yangfu Road, Suzhou Industrial Park, Huqiu District, Suzhou City

Shenzhen Office Address:Block B, Building 1, Shangzhi Science Park, 380 Guangming Avenue, Guangming District, Shenzhen 1405

Copyright © Hubei True Light 3D Sensing Technology Co., Ltd.