Daily Sensor News: TrueLight 3D Sensing, a sensor company, completes a nearly tens of millions of dollars angel round of financing; TSMC shifts to Germany after encountering setbacks in US factory construction; Intel launches a glass substrate plan

Release time:

2023/09/20

New sensing product

[Barcelona Institute of Science and Technology: Researchers design semi-transparent image sensors for eye-tracking applications using graphene and quantum dots]

A team of researchers from the Barcelona Institute of Science and Technology (ICFO) and the Barcelona startup Qurv Technologies have designed flexible, near-transparent graphene-enhanced image sensors that can be hidden in plain sight.

Based on graphene and quantum dots, the sensors can be directly integrated into glasses or curved windshields, positioned in front of the user's eyes. Frank Koppens said this could make eye-tracking hardware less bulky, improve gaze detection accuracy, and reduce computational complexity. Frank Koppens is the co-lead of this research and co-founded Qurv in 2020.

He stated, "In mirrors or shop windows, smart sensors and cameras can be integrated into the glass to sense human gestures, while it's simply impossible to integrate photodetectors into glass using traditional materials."

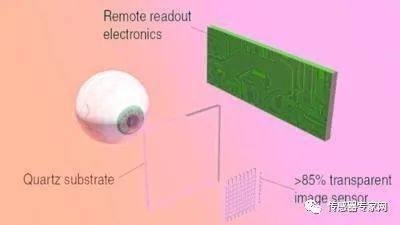

The semi-transparent sensors can be integrated into glasses, while their readout electronics are placed on the sides of the frames, and the transparent image sensors can achieve many other Applications.

Eye tracking usually involves reflecting infrared light from the user's eyes and using image processing algorithms to analyze the reflected signal to measure eye position, movement, and pupil dilation, etc. Light-emitting diodes and one or more infrared cameras are mounted away from the line of sight, such as along the lens frame of VR/AR glasses.

To create the semi-transparent image sensor, Koppens, Qurv CTO Stijn Goossens, and their colleagues combined the properties of two nanomaterials. Graphene is an excellent conductor and also very good at converting photons into electrons and positively charged holes, but it absorbs very little light. Quantum dots, on the other hand, are semiconductor nanocrystals and are excellent light absorbers.

Therefore, the team deposited graphene on a transparent quartz substrate and then coated it with an ultrathin layer of quantum dots only tens of nanometers thick. The quantum dots absorb photons and transfer them to the graphene, which converts them into voltage.

The graphene-quantum dot photodetector is said to have a transparency of about 90%. Koppens said that they absorb less light than traditional silicon photodetectors, so their overall performance "can never reach the same level." But he added that they convert absorbed light into electrical signals with about 60% efficiency, which is "quite high, comparable to traditional silicon photodetectors, and sufficient for eye tracking."

Koppens and his colleagues first reported this basic photodetector a decade ago, and since then, significant progress has been made in efficiency and scalability. They now use common vapor deposition techniques to grow graphene on 300nm wafers to manufacture photodetectors.

As a demonstration, the researchers fabricated an 8x8 graphene quantum dot photodetector pixel array, with each pixel measuring 60x140 micrometers. The pixels are connected to signal processing electronics via wires made of indium tin oxide (ITO), a commonly used transparent electrode material. The researchers projected pixelated black and white images onto the array and reconstructed them by reading the signals from each photodetector. Most patterns could be reconstructed by the array, but they were not perfect.

Koppens said that more work needs to be done to improve performance, and Qurv researchers are now planning to further improve the resolution and speed of the image sensors and develop methods to reliably mass-produce them.

Sensing dynamics

[Optical Micro-Nano 3D Sensor Company "TrueLight 3D Sensing" Completes Nearly 10 Million Angel Round Financing, Peakview Capital Leads Solely]

TrueLight 3D Sensing, a manufacturer of optical micro-nano 3D sensors, has completed a nearly 10 million RMB angel round of financing, which was solely led by Peakview Capital.

It is understood that this round of financing will be used for research and development investment in the next generation of precision optical three-dimensional imaging technology platforms, early team building, and new product development. The company uses spectral confocal imaging technology to build the next generation of precision optical three-dimensional imaging technology platforms, and aims to become a world-leading provider of micro-nano optical three-dimensional sensing and measurement and testing instruments.

Regarding this round of financing, Li Gang, the early project manager of Peakview Capital (FreeSFund), said that with the continuous and rapid development of related industries driven by bottom-up advanced manufacturing process capabilities and their applications, the demand for high-precision imaging, especially micro-nano three-dimensional imaging, will also increase rapidly. "The Chu Guang team, with years of industry experience and scientific research accumulation, relying on spectral confocal microscopy and coded imaging technologies, can quickly provide solutions for high-speed and high-precision measurement of micro-nano three-dimensional structures. It is believed that under the wave of related industrial upgrading and advanced manufacturing, Chu Guang can become a leading precision measurement platform enterprise."

For a long time, due to environmental and efficiency requirements, high-level manufacturing quality inspections have been difficult to apply to mass production sites. However, in advanced manufacturing fields such as semiconductors, new energy, and panel displays, the complex, fast, high-precision, and high-yield requirements of manufacturing processes have posed challenges to micro-nano detection of complex process in mass production. Efficient and stable measurement and detection methods, technologies, and equipment for micro-nano three-dimensional structures will face a huge and growing rigid market space with the booming development of related industries.

In the view of TrueLight 3D Sensing, it is precisely because of the high requirements for precision and efficiency in the micro-nano manufacturing field that 99.9% of visual inspection instrument manufacturers in China still remain in the traditional visual route, focusing on peripheral low-precision detection needs, and only a few have entered the field of micro-nano three-dimensional imaging in micro-nano manufacturing processes. As of now, the competitive landscape of the micro-nano three-dimensional imaging industry is characterized by high technical barriers, few players, and huge growth potential.

According to Aiqicha, founded in November 2022, Hubei TrueLight 3D Sensing Technology Ltd., headquartered in Wuhan Optics Valley, Hubei Province, is an optical micro-nano 3D sensor technology R&D enterprise relying on the Department of Instrument Science and Technology of Huazhong University of Science and Technology, with more than 20 years of scientific research and project development experience in optical micro-nano three-dimensional sensing and measurement, and owns multiple core patents.

More news

TrueLight 3D Sensing, a domestic manufacturer of precision optical imaging instruments, has completed tens of millions of yuan in angel+ round financing, according to Hard Krypton. The investors are Yuanhe Origin, Optics Valley Investment, and Changshu National Development Venture Capital, with angel round investor Peakview Capital continuing to invest. This round of financing will primarily be used for the continued R&D of the current optical 3D imaging technology platform and the establishment of a market team, accelerating the commercialization process.

2025-03-21

TrueLight 3D Sensing relies on the Instrument Science and Technology Department of Huazhong University of Science and Technology and a team of expert researchers, possessing numerous core patents and abundant technological reserves.

2025-03-21