Backed by Huazhong University of Science and Technology's technology team, a Wuhan high-end equipment company receives tens of millions in financing | Hard Krypton exclusive

Release time:

2025/03/21

TrueLight 3D Sensing, a domestic manufacturer of precision optical imaging instruments, has completed tens of millions of yuan in Angel+ round financing. The investors are Yuanhe Origin, Optics Valley Investment, and Changshu National Development Venture Capital, with the Angel round investor, Peak Capital, continuing to invest. This round of financing will primarily be used for continued research and development of the current optical 3D imaging technology platform and the establishment of a market team, accelerating the commercialization process.

TrueLight 3D Sensing, established in 2022, focuses on developing an optical 3D imaging platform based on spectral confocal technology. Its products can be used in the semiconductor, high-end 3C electronics, new energy, silicon photonics devices, thin-film materials, and ultra-precision manufacturing industries for inspection and measurement.

In recent years, the manufacturing industry has undergone continuous upgrades, with manufacturing precision continuously refined and improved, and material structures rapidly iterating. Therefore, traditional measurement and detection solutions are gradually unable to meet the needs of emerging industries. Taking the semiconductor industry as an example, major manufacturers are starting to produce chips using advanced packaging processes, and chip structures are transitioning from two-dimensional to three-dimensional structures. Li Min, founder of TrueLight 3D Sensing, told Hard Krypton that existing measurement technologies have difficulty accurately and efficiently measuring three-dimensional chips with complex micro-nano structures such as high aspect ratios. High-efficiency micro-nano precision 3D measurement and detection will be a future demand trend in the semiconductor industry.

In addition to the ultra-precision manufacturing field, the iteration of 3C industry components has also led to more and more new situations, new materials, and new media placing higher demands on detection processes. For example, the curved and foldable processes used in current Mobile phone screens make it difficult for traditional measurement technologies to meet the precision requirements of production line inspections.

Li Min introduced to Hard Krypton that the micro-nano manufacturing field has extremely high requirements for precision and efficiency; correspondingly, it also requires more precise and advanced measurement and detection technologies. Currently, the vast majority of visual inspection instrument manufacturing companies in China are still on the traditional visual route, only able to meet the peripheral low-precision detection needs. The few companies involved in micro-nano 3D imaging also use traditional technical routes, with a high dependence on foreign precision optical hardware.

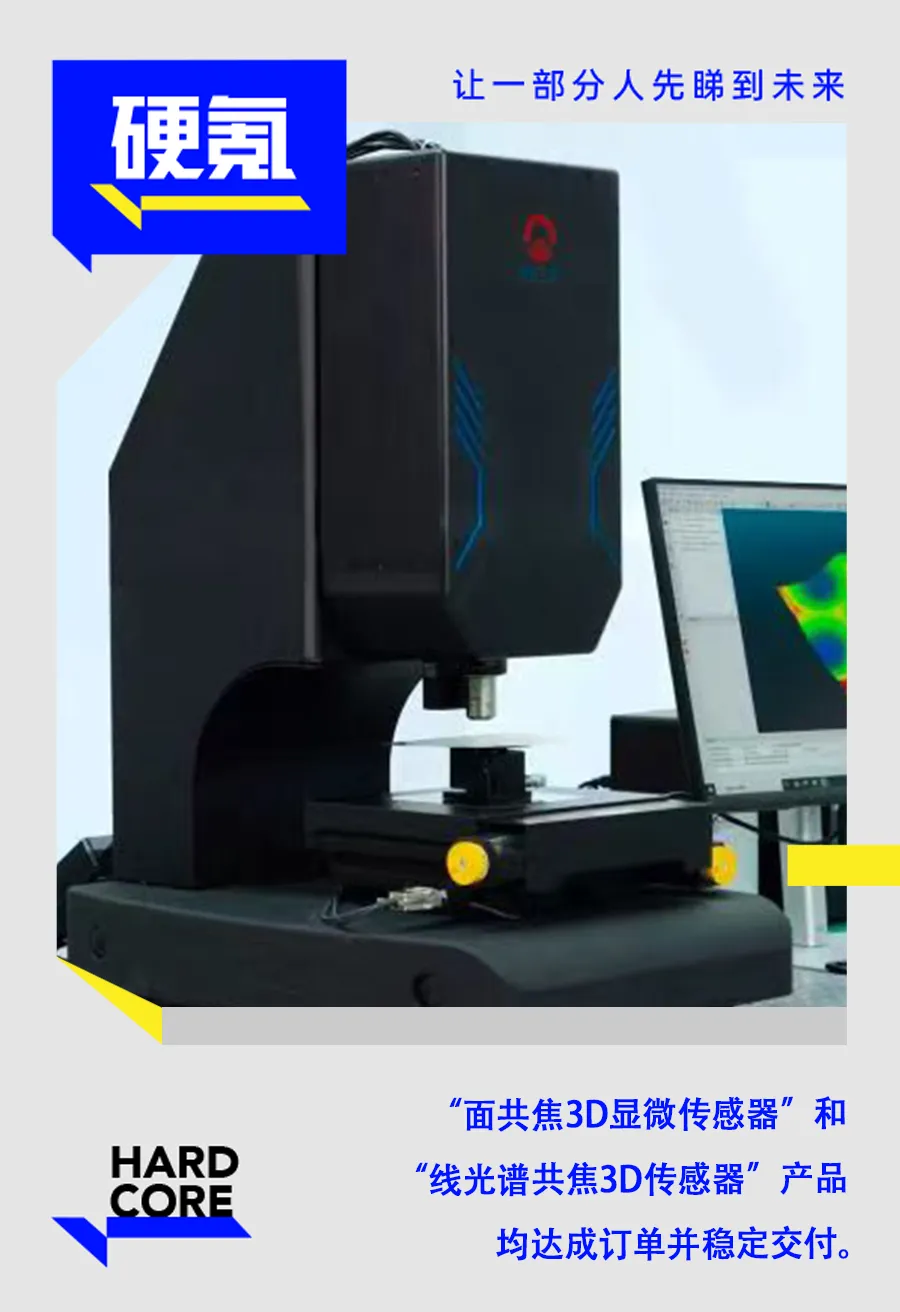

Based on this, TrueLight 3D Sensing uses a completely new technical path in its fully self-developed "surface confocal 3D microscopic sensor," using AI algorithms to optimize 3D point cloud processing. In other words, it projects a wide frequency range of structured light onto the surface of the sample being measured, then captures the surface structured light imaging through a microscope and performs tomographic analysis to reconstruct its surface morphology, thereby achieving the generation of a "snapshot" nanoscale precision 3D multi-layer morphology in a single scan. This surface confocal product is the world's first commercial product using "array light + confocal imaging" technology.

Currently, the cutting-edge products on the market are mainly divided into two categories: one is the laser scanning confocal 3D microscopic product, and the other is the digital zoom 3D microscopic product, both belonging to traditional technical routes. Li Min revealed that TrueLight 3D Sensing's surface confocal 3D microscopic product achieves a breakthrough through algorithm optimization and simulation, reducing reliance on precision optical hardware, and achieving leading performance in key Technical Index while significantly reducing hardware costs.

In addition, TrueLight 3D Sensing's other product, a line spectral confocal 3D sensor, has also achieved mass production.

In terms of commercialization, both the "surface confocal 3D microscopic sensor" and the "line spectral confocal 3D sensor" products have received orders and are being stably delivered.

In terms of the team, TrueLight 3D Sensing relies on the expert research team of the Department of Instrument Science and Technology at Huazhong University of Science and Technology, possesses multiple core patents, and is closely connected to cutting-edge research results. At the same time, the engineering and operation team has more than 10 years of experience in the commercialization of 3D imaging. Among them, Professor Liu Xiaojun, chief scientist of TrueLight 3D Sensing, has long been engaged in the research and development of micro-nano 3D measurement technology, completing multiple national key projects, and has extensive technical accumulation in the field of optical micro-nano 3D perception and measurement. Li Min, founder and CEO of TrueLight 3D Sensing, is a serial entrepreneur who has served as a co-founder and business leader in semiconductor and 3D vision startups.

Investor Opinion:

Du Min, Partner of Yuanhe Origin, the lead investor in the Angel+ round: "Mr. Li has many years of experience in the development and application of high-end equipment in the pan-semiconductor field. The combination of micro-nano optics and algorithms with Professor Liu and the Huazhong University of Science and Technology technical team has formed TrueLight 3D Sensing's core underlying technology and market-oriented product design capabilities. The company's self-developed line confocal and surface confocal detection sensors have complete independent intellectual property rights and can solve the 3D Size detection of micro-nano structures in advanced packaging and 3C electronics fields, in line with the global trend of advanced manufacturing. We are very pleased to have the opportunity to invest in TrueLight 3D Sensing, to form a broader micro-nano manufacturing application ecosystem, and jointly contribute to the development of advanced manufacturing in China."

More news

TrueLight 3D Sensing, a domestic manufacturer of precision optical imaging instruments, has completed tens of millions of yuan in angel+ round financing, according to Hard Krypton. The investors are Yuanhe Origin, Optics Valley Investment, and Changshu National Development Venture Capital, with angel round investor Peakview Capital continuing to invest. This round of financing will primarily be used for the continued R&D of the current optical 3D imaging technology platform and the establishment of a market team, accelerating the commercialization process.

2025-03-21

TrueLight 3D Sensing relies on the Instrument Science and Technology Department of Huazhong University of Science and Technology and a team of expert researchers, possessing numerous core patents and abundant technological reserves.

2025-03-21