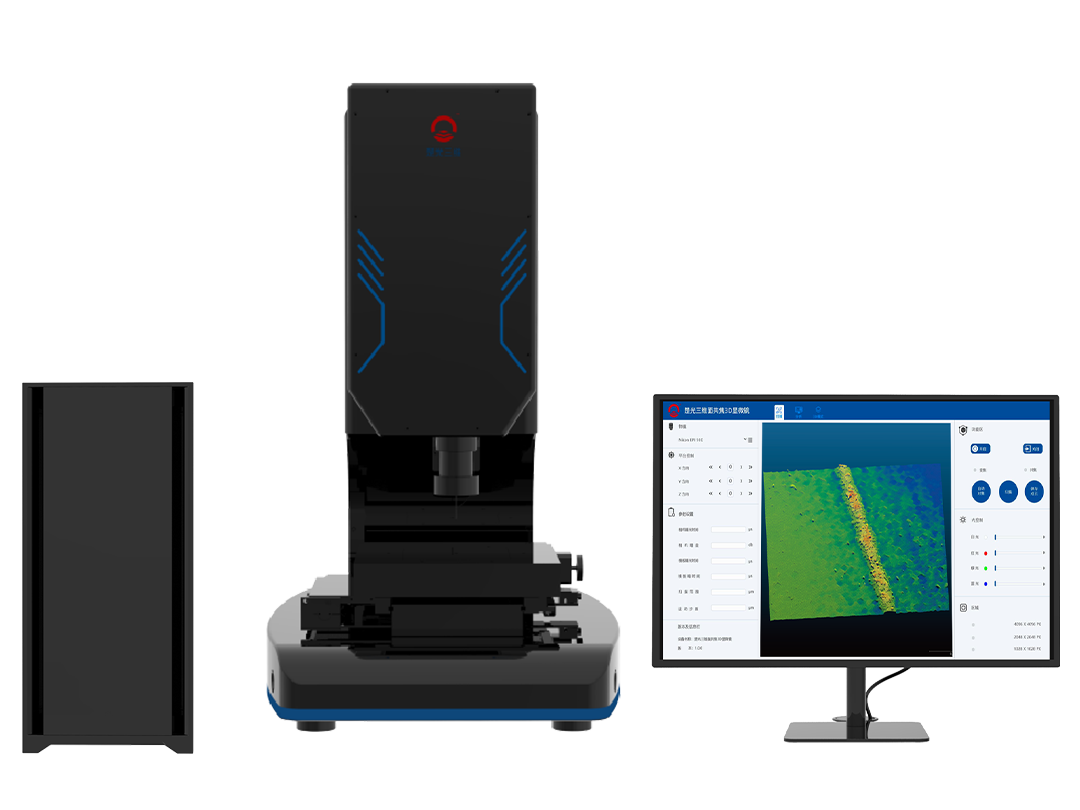

AMS Areal confocal 3D microscope

Technical Principle

Based on the principle of widefield microscopy, it utilizes structured light illumination to modulate the surface information of the object, removing out-of-focus signal interference. A 3D micro-surface topography is obtained through vertical axial scanning. It is suitable for both complex feature surfaces (such as scattering surfaces) and smooth surfaces. The Z-axis accuracy can be flexibly adjusted from 1nm to 1μm according to the application scenario.

World's first commercially available product with "array light + confocal imaging" technology | |

| ● Unique areal light scanning confocal technology brings higher efficiency and stronger imaging capabilities ● Cross-scale, cross-material, cross-structure compatibility ● Integrating artificial intelligence to explore more application possibilities |

Schematic Diagram | |

Product Features

● New generation fully autonomous desktop confocal 3D microscope/profiler

● Surface scanning, cross-scale, true color, fast imaging

| Cross-scale compatibility:Compatible with high-precision mode (limit 1nm) and long-range (30mm), submicron precision mode High Adaptability:Adaptable to smooth surfaces, complex surfaces, highly reflective materials, and transparent materials Multifunctional:Measurement of roughness, warp/flatness, three-dimensional profile, size, XY large field of view stitching, surface image, etc. Low Maintenance Cost:LED light source, stable, reliable, and long lifespan Openness:Supports export of original true color images and 3D point clouds for convenient AI analysis |

| Confocal 3D Microscope Product Image |

Product Introduction

Cross-scale Application | ==> | 1 Confocal 3D Microscope = 1 Laser Confocal 3D Microscope + 1 Super-depth 3D Microscope | ||

Traditional Technology Products |

| Application Types | ||

①Super-depth Microscope Digital ②3D Microscope Laser Confocal ③3D Microscope White ④Light Interferometer | <==substitute |  | applications==> | ①Defect observation and analysis ②Key dimension measurement ③Surface profile ④analysis Roughness detection ⑤Transparent film thickness detection... |

Model Name | AM 100 (Large Range) | AM 10 (High Precision) | AM 1 (Ultra-high Precision) | |||||||||||||||||||||||||||||||||||

Principle | White light confocal | White light confocal | White light confocal | |||||||||||||||||||||||||||||||||||

Axial Scanning Device | Motor | PZT+motor | PZT+motor | |||||||||||||||||||||||||||||||||||

Axial accuracy(μm) | 0.1 | 0.01 (PZT), 0.1 (Motor) | 0.001 (PZT), 0.1 (Motor) | |||||||||||||||||||||||||||||||||||

Range μm① | 30000 | 500 (PZT), 30000 (Motor) | 400 (PZT), 30000 (Motor) | |||||||||||||||||||||||||||||||||||

XY Stage mm② | 100 x 100 | 100 x 100 | 100 x 100 | |||||||||||||||||||||||||||||||||||

Size (HxWxD) mm | 780 x 475 x 595 | 780 x 475 x 595 | 780 x 475 x 595 | |||||||||||||||||||||||||||||||||||

Weight (kg) | 55 | 55 | 55 | |||||||||||||||||||||||||||||||||||

Optional Objective③ |

| |||||||||||||||||||||||||||||||||||||

Note | ①Limited by the objective lens working distance, the maximum range is 30mm; motor stroke 100mm; ②Can be customized according to requirements, supporting size matching, such as 12-inch wafers; ③Objective lens is not standard; select objective lens according to usage needs; ④A complete microscope includes a measuring head, objective lens, base, controller and display, measurement software, gauge blocks, among which the objective lens and gauge blocks are optional. | |||||||||||||||||||||||||||||||||||||

Key words:

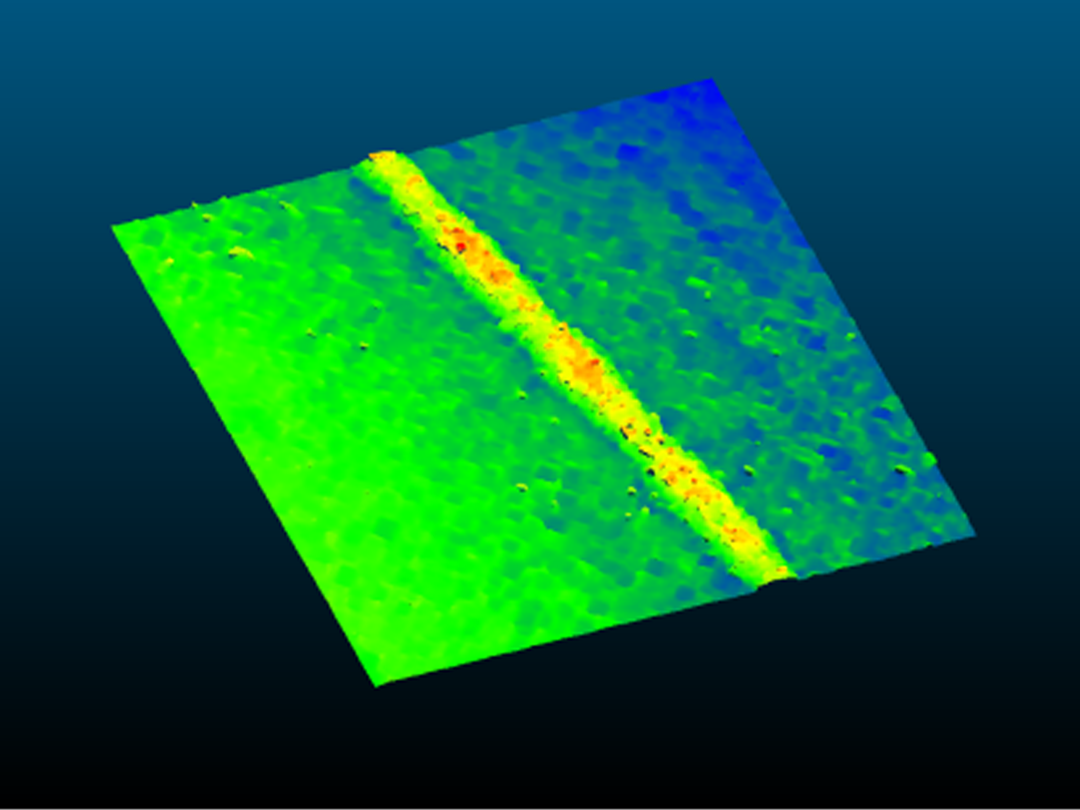

Solar cell silicon suede pyramid, grid line measurement

PV application: Solar cell silicon suede pyramid, grid line measurement

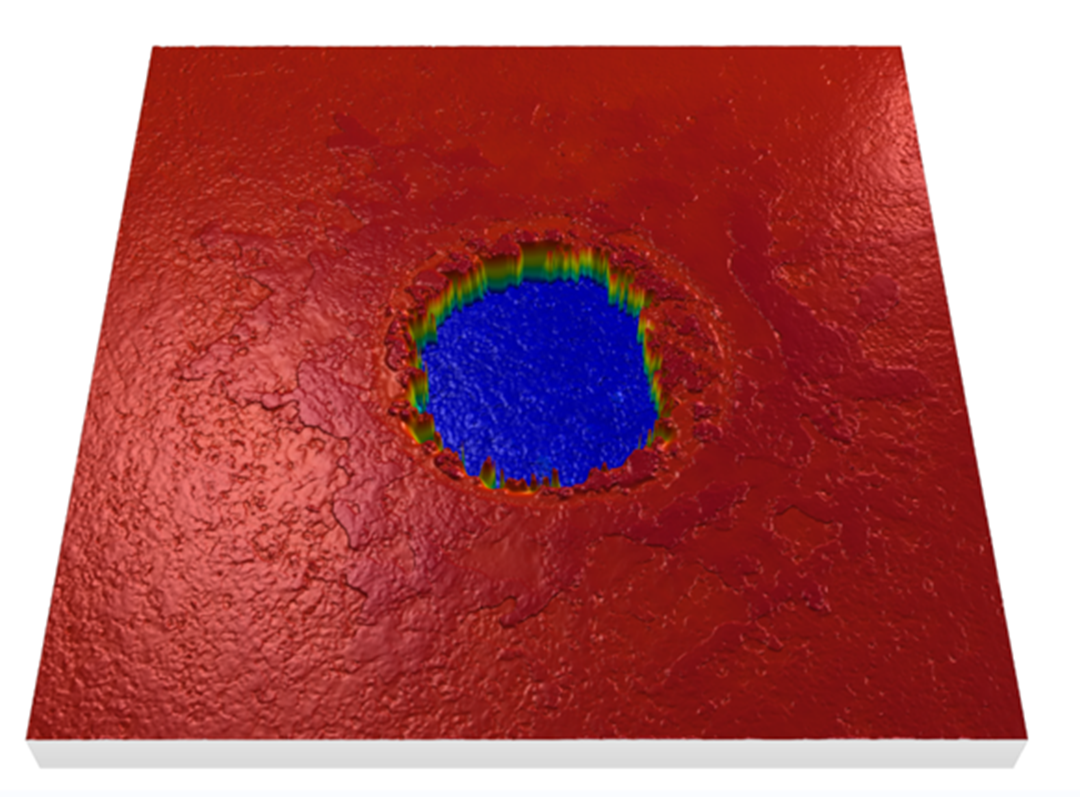

High-end IC carrier bore hole depth measurement

High-end PCB manufacturing:Laser drilling of IC substrate application: High-end IC carrier bore hole depth measurement

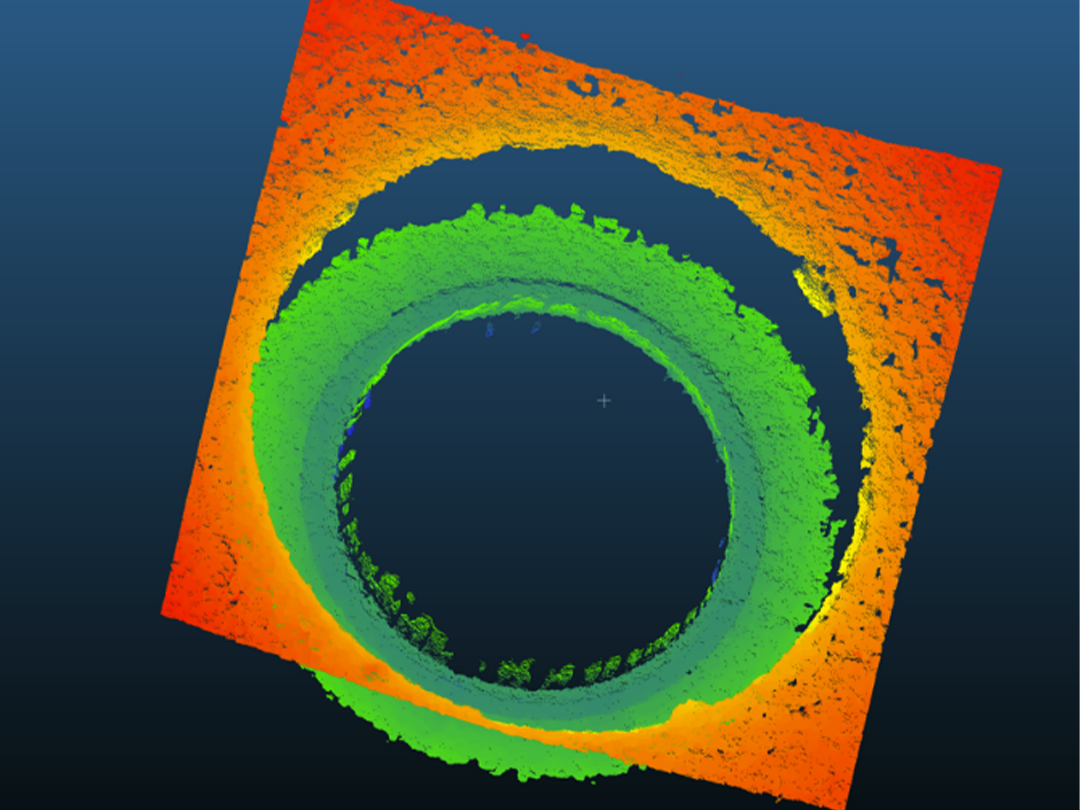

Back bore hole depth measurement, up to 8mm deep hole

High-end PCB manufacturing:back drilling Application: Back bore hole depth measurement, up to 8mm deep hole

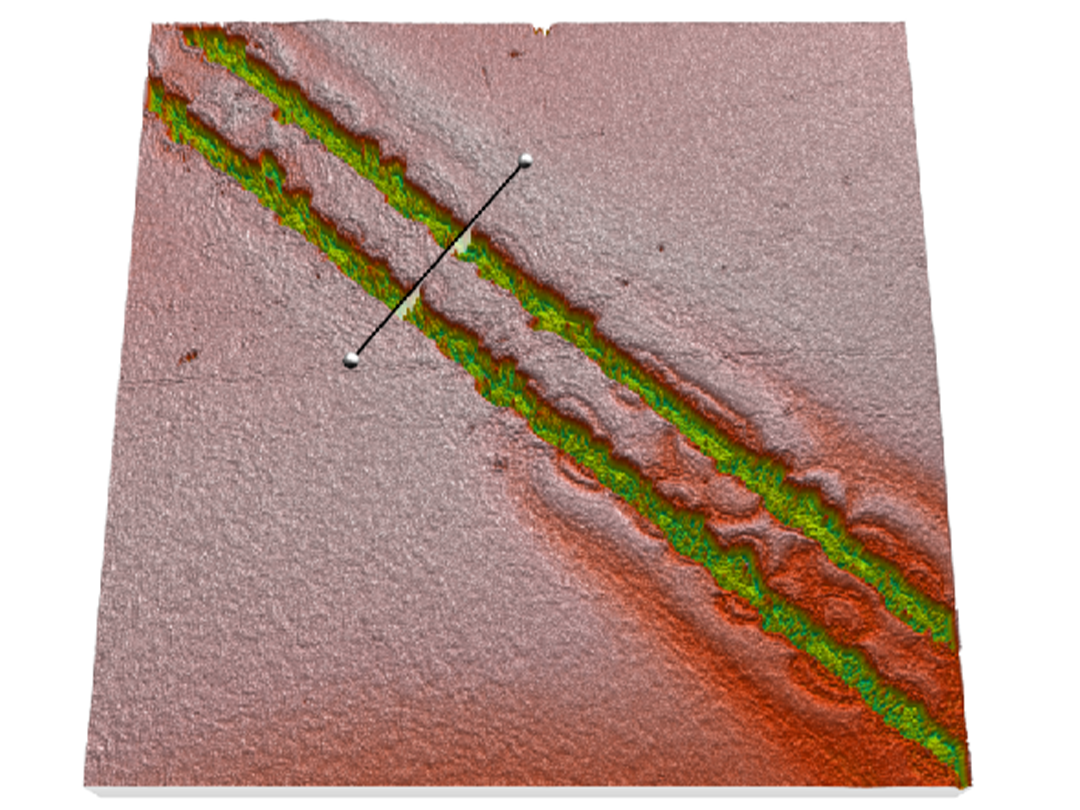

Measurement of the depth and width of the cutting groove after the wafer laser cutting

OSAT (Front-End) application: Measurement of the depth and width of the cutting groove after the wafer laser cutting

AMS Areal confocal 3D microscope

New generation fully autonomous desktop confocal 3D microscope/profiler

AM Areal confocal 3D microsensor

New generation fully autonomous confocal 3D microscopic sensor/probe